SERVICES

WELCOME TO PRENTAC

Value Delivery Assured

PRENTAC brings a full array of Professional Development Programs for core engineering disciplines including Chemical, Mechanical, Electrical, Instrumentation and Civil. You will find the professional development programs both for fresh engineering graduates and experienced engineers and, are delivered in multiple modes including classroom, virtual online and online for Individuals as well as Corporates.

PRENTAC professional development programs are authored and delivered by respective discipline professionals with a minimum of three decades experience. The professional development programs enhance your career prospects in ever changing job market, increasing your adaptability, and offering you more employment flexibility.

ENQUIRE NOW

Learning A Continuous Journey, Not A Destination

It is essential for fresh engineering graduates to devote time for professional development to close the gaps between academic learning and industry demands. The experienced engineers through structured Competency Gap Analysis (CGA) can identify the gaps and get customized professional development programs.

This course is suited for both fresh and experienced Chemical Engineers who have limited or no exposure to process engineering field and wish to work as Process Engineers in EPC/PMC companies, in oil/gas production companies, in refining/petrochemical/chemical manufacturing companies, as well as in Research & Technology companies.

This course is suited for experienced Chemical Engineers who have limited or no exposure to process safety in design/process safety management and wish to work as Process Safety Engineers in EPC/PMC companies, in oil/gas production companies, in refining/petrochemical/chemical/Pharmaceutical manufacturing companies, as well as in Research & Technology companies.

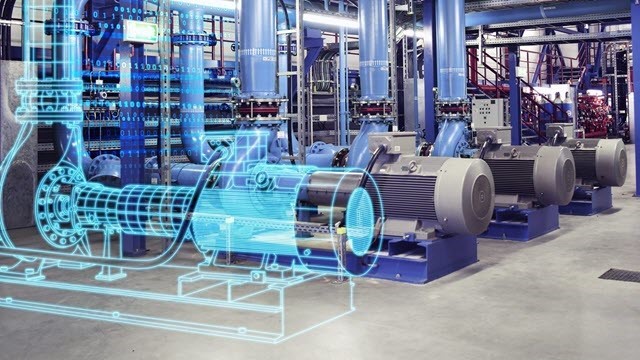

This course is suited for fresh /experienced Chemical/mechanical Engineers who have limited or no exposure to rotating equipment wish to work as Rotating Equipment Engineers in EPC/PMC companies, in oil/gas production companies, in refining/petrochemical/chemical/Pharmaceutical manufacturing companies, as well as in Research & Technology companies.

Technical Quality Assurance / Process simulations / Process Calculations / PFD / MB Preparation / Equipment Design / P&ID preparation / Equipment Layout / Hydraulic Calculations / Equipment Datasheets / Equipment Specifications / Technical Bid Analysis / PO Specification / Vendor Data review / Preparation of Operating Manuals / As built P&ID Updating / Safety Devices calculations & documentation / HAZOP Review Support.

Relief Devices and Flare system calculations & documentation

Process Safety Management (PSM)

Process Safety Audits

HAZOP Reviews / SIL Classification

Risk Assessment /Layer of Protection Analysis (LOPA)

Techno-Economic Project Feasibility Studies

Detailed Project Report / Sensitivity Analysis

Licensor Selection / Technology Assessment and Evaluations

Basic Engineering

FEED and Detail Design

Operator Training Simulator Development

Training your staff in Advanced Process Safety, Conduct a comprehensive Process Safety Audit of your facilities, Establish Process Safety Management (PSM) System for your facility, Provide technical assurance on Process Safety in design deliverables during project execution, Integrate PSM with our proprietary PSCDIMS© Software,Training your staff in Advanced Process Safety

COURSES | GALLERY | LINKS

Certificate Courses

APE-Applied Process Engineering

ACCPS-Process Safety & Design

ACCPD-Project Development & Economics

ACCOG- Oil & Gas Production Facilities

ACCPPU- Process Plant Utilities & Design

Certificate Courses

CCFIC-Field Inst.& Basic Process Control

CCPS-Process Simulations

CCRFS- Relief & Flare Systems

CCPC-Pumps & Compressors

Workshops

HAZOP

SIL Classification

Process Safety Awareness

Process Engineering for Non-chemical Engineers

Bio-process engineering

Project Engineering

Project Cost Estimation

Workshops

Pumps

Compressors

Storage Vessels /Tanks

Heat Exchangers

Hydraulic Calculations

Relief Valve Sizing

Control Valves

Risk Assessment